Level Control - Bindicator

Level control is essential for many industrial and commercial applications, ranging from simple water tanks to complex chemical processing systems. Industrial applications often require control to maintain safe and...

What is the role of level control systems in managing dry bulk products?

Level control for dry products provides accurate monitoring of material levels in bins, silos, and hoppers to make sure of efficient operations and minimize waste. Versatile devices, including rotary paddle switches, vibrating rods, capacitance probes, and radar sensors, cater to different applications and are built to withstand harsh environments, providing long-lasting performance. These devices feature user-friendly designs for quick integration, reducing downtime and installation costs. Advanced sensors ensure precise level measurement, maintaining optimal inventory levels, while low maintenance requirements save time and operational costs.

What Devices Are Common for Dry Bulk Level Control?

Common devices for dry bulk level control include:

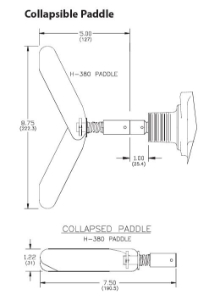

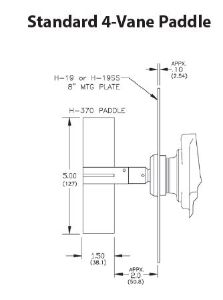

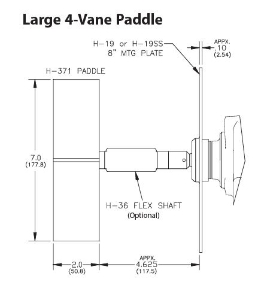

- Rotary Paddle Switches: Detect bulk materials by halting rotation when the material reaches the paddle.

- Vibrating Rod Sensors: Detect material presence by using vibration and are suitable for various bulk materials.

- Capacitance Probes: Measure changes in capacitance caused by material presence.

- Radar Sensors: Provide non-contact, continuous level measurement, making them ideal for dusty environments.

What are the Benefits of Advanced Level Control Solutions?

The benefits of advanced level control solutions include:

- Enhanced operational efficiency, optimizing production processes, reducing downtime, and increasing output.

- Cost savings by preventing overfilling and material shortages, all while reducing waste and operational costs.

- Reliable level measurement for safe storage and handling of materials, preventing spills and accidents.

- Real-time monitoring to help maintain optimal inventory levels, improving supply chain efficiency.

Level switches are used to detect and control the level of liquids that trigger alerts or activate pumps and valves based on predetermined levels to prevent overflows or shortages. Level switches are used in industries such as water treatment, chemical processing, and food production, for efficient process control and preventing environmental hazards.Browse our selection below or contact us to speak to a product expert.

$102.64

$1,061.86

Subject to factory lead times

$53.29

$68.10

$55.27

$57.24

$179.23$184.00

$180.60

$591.13

Subject to factory lead times

$102.64

$1,061.86

Subject to factory lead times

$53.29

$68.10

$55.27

$57.24

$179.23$184.00

$180.60

$591.13

Subject to factory lead times